Trucker Access › Forums › Diesel News › Windrose Trucks Coming to U.S. in 2025 – Equipment

- This topic has 0 replies, 1 voice, and was last updated 8 months, 2 weeks ago by

EazyRiDer66.

EazyRiDer66.

-

AuthorPosts

-

July 13, 2024 at 5:00 am #29633

EazyRiDer66Keymaster

EazyRiDer66Keymaster

This is not a spruced-up Tesla Semi. It’s a new BEV from Chinese truck maker, Windrose. The company intends to begin production on the truck and have it in American customer hands next year at a price of about $250,000.

If, while wandering around the ride and drive area at ACT Expo in May, you thought your eyes were deceiving you, fear not. The Tesla look-alike truck you saw was not a Semi with a facelift. It was a new BEV from Chinese truck maker, Windrose. The company intends to begin production on that truck and have it in customer hands here next year.

Windrose plans to build a “global chassis” based roughly on current European specs. Published specs suggest the first iteration will have a range of up to 670 km (415 miles). That’s fully loaded with a planned tare weight of 25,000 pounds.

While several variants are planned, it will come to market with a 730 kWh NMC (Nickel manganese cobalt) battery pack and a price tag of around (US) $250,000.

Ambitious Plans

Major Windrose components such as the chassis, e-axles, suspension and the batteries are to be produced and partially assembled in Suzhou, China. Final assembly for the Asian and Oceania markets will also take place there.

Final assembly for trucks bound for the EU will take place in Antwerp, Belgium.

The chassis has a distinctly European look and feel. The area behind the cab houses some of the power electronics and battery thermal management systems. Unlike the Tesla Semi, the rear section of the cab interior can be configured as a small sleeper compartment.

Windrose is also building additional final assembly capacity in Savannah, Georgia for the U.S. market.

The company has very ambitious plans to deliver an efficient and cost-effective Class 8 truck battery electric truck to every major market on the planet.

With the backing and support pf several dominant Chinese manufacturers, including Anhui Jianghuai Automotive Group (JAC Group), Windrose believes it can position the truck at a better price point than the current competitors while delivering equal or better range and lower tare weight.

Company Management

Windrose is led by Stanford University MBA graduate, Wen Han. Prior to founding Windrose in 2022, Han was the chief strategy and financial officer at autonomous truck company, Plus. He’s currently Chairman and CEO of Windrose.

Haoli Chen serves as president and CTO. He’s also a co-founder of the company. Chen’s bio on the Windrose website describes him as a 20-year veteran of the truck manufacturing industry. He previously served as head of China’s 6th largest truck OEM, Anhui Jianghuai Automobile (JAC).

JAC will build and assemble the Windrose truck in Suzhou, China for Asia-Pacific markets.

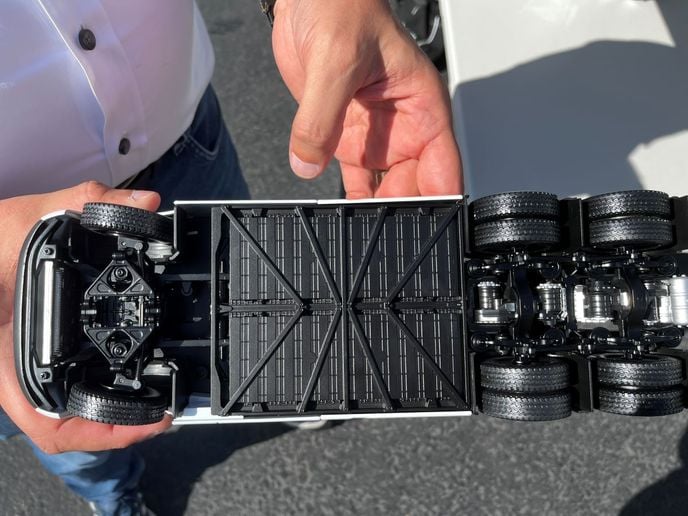

This die-cast scale model reveals the truck is driven by a tandem pair of Chinse-made e-axles equipped with four hairpin-wound liquid-cooled permanent magnet synchronous motors developing up 1,040 kW (1,414 hp). It also has independent front suspension

and a box-frame arrangement where the batteries provide stiffness and structural integrity to the frame.

Han has brought on board an advisory board of executives from leading global OEMs, Tier-1 suppliers and fleets, including Decathlon, Coca-Cola, Starbucks, J.B. Hunt, XPO, and others.

Serving as a strategic advisor for Windrose’s expansion to the U.S. market is Jason Roycht, formerly global head of fuel cell electric vehicle market development at Nikola and previously, vice president of commercial vehicles for Bosch.

The company completed the second phase of its Series B funding in April, coming away with $110 million in investment from the likes of HSBC, HITE Hedge Asset Management, and digital infrastructure specialist Goodman Group, among others.

Much of Windrose’s current effort is devoted to replicating the Chinese supply chain in Europe. The EU is more open to Chinese imports when some portion of manufacturing and production is done there.

[embed]https://www.youtube.com/watch?v=bAuTLO-uMU0[/embed]

Windrose officials have already secured supply and production agreements in the Belgian port city of Antwerp.

Han told HDT he has had discussions with potential suppliers in France.

“We are talking about a mix of production in France and assembly in Belgium,” Han said. “That way, we are able to replicate some of the Chinese supply chain in Europe.”

That supply chain consists of a vast network of manufacturers and suppliers, little known in the U.S., but who, according to Han, produce components for China’s million-truck-per-year heavy duty market. “That’s bigger than United States and Europe combined,” he emphasized.

A likely early-days scenario would see Windrose’s unique components manufactured in China and shipped to Europe for assembly. Later, some production would shift to Europe where partial assembly would occur. Eventually, the plan calls for European and Chinese made components to be shipped to the U.S. for final assembly in Savannah, Georgia.

“It remains to be seen if we should be making components in the United States,” said Han. “That’s an interesting topic to explore.”

Clearly, having home-turf production and assembly would go some distance toward avoiding or mitigating punishing tariffs on Chinese vehicle and automotive components.

A Global Platform

The Windrose truck was conceived and designed as a global platform from Day One.

It’s being engineered for compliance in every market where long-haul trucking is prevalent.

Roycht told HTD it was designed to operate in markets with 100,000-pound gross weights, i.e., China, Scandinavia, Canada and Australia.

“Building to that standard allows us to launch first in China where the gross weights are over 100,000 pounds; they are similar to Canada actually,” he said. “The frame, the axles, everything is designed for the higher load capacity. That carries over to Europe where gross weights are a little lighter, around 90,000 pounds. That basically gets us the US for free.”

The center driving position allows the company a way around re-engineering the front end to accommodate right- or left-hand drive configurations. The truck features a mirror camera system and two large display screens. It also has a full window sun-shade like many motor coaches.

Han says the center steering position is integral to its global acceptance. He said it cuts the engineering challenges to producing right- and left-hand drive trucks for various markets.

“Having one seat in the center automatically qualifies us for right- and left-hand drive,” he said. “We don’t have to worry about that anymore.”

The question of vehicle safety certification is still somewhat up in the air. Obviously, it will be engineered to meet local requirements, such as the all the U.S. DOT lighting and stopping distance rules. Since standards differ around the world, the need for specific engineering still exists.

During the course of our conversation, I mentioned components such as brakes and air compressors and that sort of thing. It was implied they intend to use Chinese suppliers there rather than familiar U.S. suppliers.

However, Roycht added that Windrose intends to consult with some large potential core customers on the issue.

“We’ll be working through that with a group of lead customers in the U.S. about what they want to see in terms of the high-cost components,” he said. “I think they will more than like — like I did — the partners Windrose has. In terms of the wearable items like brakes, or maybe some of the ADAS stuff, we’ll be working through that on a case-by-case basis.

“But we will be 100% true to the cost and quality targets we have for this truck.”

Optimized for Weight and Range

“The best way to optimize the range, weight and cost is to do a ground up, design,” Han said. “And that’s what we have here.”

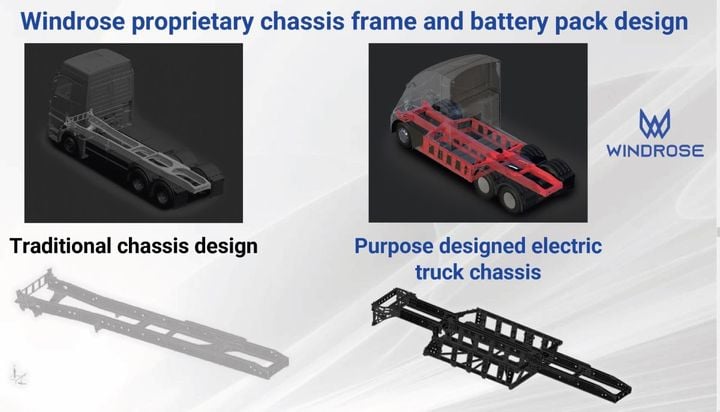

The rear of the frame is a familiar ladder configuration. In the middle is the box frame that holds the batteries, and there there’s another extension out front for the steering and suspension components. Windrose says that design is lighter and uses less material that a typical truck frame, and it relies on the batteries for its structure.

Windrose will offer several different variants of the truck, similar to what Tesla does.

The rear of the frame is a familiar ladder configuration. In the middle is the box frame that holds the batteries, and there there’s another extension out front for the steering and suspension components. Windrose says that design is lighter and uses less material that a typical truck frame, and it relies on the batteries for its structure.

“Ours is going to be probably 400 and 200 miles, not 500 and 300 miles,” Roycht said. “At 200 miles, taking out half of the battery capacity, it’s gonna reduce the weight. The delta will be at least 3,000 pounds, and there’ll be a delta on the price as well.”

Roycht said the truck, as displayed at ACT Expo, weighs 26,000 pounds with 730 kWh LFP (lithium iron phosphate) battery cells. The plan is to switch to NMC cells.

“We think 24,000 pounds is completely achievable with 730 kWh with NMC batteries,” he said, adding, “If you make some assumptions about energy density, and the weight improves by 10% over three years, our 24,000 pound truck becomes 23, or 22,000.

“Still, at 24,000 pounds we’re getting very good reception with the customers. It’s a nice spot to be in.”

A Tesla Wannabe?

So – is the truck just a “Chinese Tesla”?

It would be easy to come to that conclusion, but there are some styling features that separate the two. More likely it’s that the shape is closer to what could be called the ideal frontal profile.

Windrose claims the truck has an aerodynamic drag coefficient of 0.275, while the drag coefficient of the Tesla is reportedly 0.36.

Since the truck was designed for optimum range, aero would have been a consideration. And given there’s no longer any need for a hood under which to stuff all the power electronics and cooling packages, Windrose says it has designed the truck for efficiency with little regard to what we might call brand recognition. In other words, just because a truck is Brand A, it doesn’t have to be visually recognizable as such.

“I think, globally, trucks will start to evolve into something similar to the Windrose design; no more real straight cab-overs and no more real need for long nose trucks,” Roycht said. “That’s the optimal aerodynamics. Having one seat in the center makes that design a little easier.”

The Road Ahead

Following its appearance at ACT Expo, the truck was trailered back east to Illinois where it was charged up before driving the rest of the way to New York. From there it turned around and drove back to Los Angeles.

That was a single trip of 3,000 miles using public charging all the way,” Han said. “There was no need for special charging. We stopped at 18 public charging stations, which is great as far as infrastructure goes.”

There is only one door on the truck, but access to the cab is safe and easy. Drivers will not be climbing in and out on the traffic side of the vehicle. Under the hood is a storage area, much like a trunk.

The next variant of the truck to come to the U.S will be equipped with both CCS 1 and MCS (megawatt charging system).

“That truck will be the first truck ever to be compatible with both charging standards on the same truck,” Han claimed.

Earlier this year, BorgWarner, through its Chinese New Energy group, announced it was jointly developing 960kW fast-charging infrastructure for electric long-haul trucks. These chargers are to be installed properties owned by global industrial real estate company, the Goodman Group — who is also one of Windrose’s investors.

The fast-charging technology enables Windrose long-haul truck to replenish around 400km of range in under 36 minutes.

BorgWarner has tailored a 960kW liquid-cooled high-power supercharging pile, consisting of a charging host and two liquid-cooled charging terminals. It can support dual-gun single-vehicle high-power super-fast charging, with a single-gun maximum output of up to 600A.

When the truck is configured for Europe it will have a shorter wheelbase, likely a 4×2 configuration, but the chassis will be essentially that same. And aside from some local requirements, the heavy engineering work will have already been done.

Roycht said Windrose has already completed some hot and cold environment testing as well as high-altitude testing.

Han said to date, they have pre-sold 1,000 trucks in the U.S. and 200 trucks in China.

“We didn’t build this truck to be one-size-fits-all global truck. It’s a one-size-fits-enough truck,” Roycht explained. “We don’t need to go for 100% market coverage. We are prepared to have a usable truck in every market that’s big for trucking. And that’s really exciting.”

-

AuthorPosts

- You must be logged in to reply to this topic.