Trucker Access › Forums › Diesel News › Are Air Disc Brakes Worth It? – Equipment

- This topic has 0 replies, 1 voice, and was last updated 10 months, 1 week ago by

EazyRiDer66.

EazyRiDer66.

-

AuthorPosts

-

June 2, 2024 at 6:00 pm #23542

EazyRiDer66Keymaster

EazyRiDer66Keymaster

Brake fade is a thing of the past with air disc brakes. On repeated hard stops and on long descents, brake performance improves as operating temperatures increase.

Our first tango with disc brakes back in the 1980s didn’t go well. What’s the euphemism? Ahead of the market. Materials weren’t up to the challenge, they were difficult to package, and were generally considered unreliable. It’s hardly fair to compare those brakes with today’s disc brakes, but some fleets have long memories, it seems.

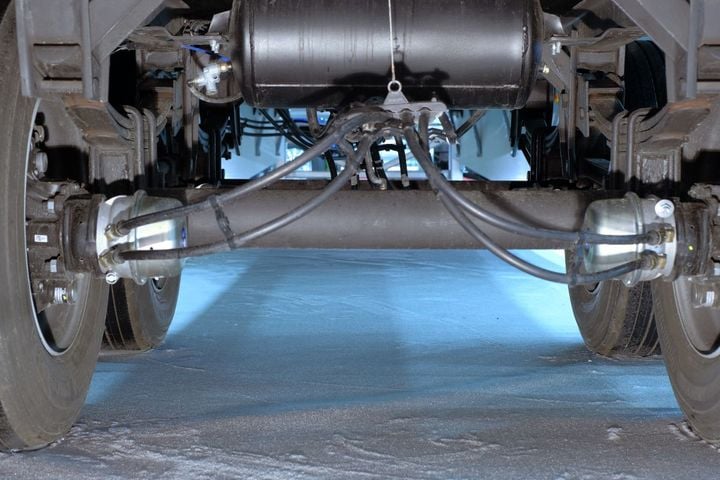

Ever since air disc brakes reemerged in North America on the early aughts, fleets have been wondering if they should switch from drums to discs. The ATA’s Technology and Maintenance Council takes up the question every few years. The group did so again this year at its annual meeting in New Orleans, presenting an S.6 Chassis & Brake System Study Group Session called, “Air Disc Brakes: Are they Worth It?”

If there’s a single-line take away from a 90-minute presentation, it would be, yes, ADB are worth the trouble it takes to switch, but not in every case.

Almost nothing in trucking is one-size-fits-all. Why should brakes be any different?

Uptake is Improving

The disc brakes that emerged in the re-introduction were substantially better than their predecessors. For example, they had internal actuators and internal automatic adjusters. The internal mechanisms were sealed from the elements, including the slide pins. That turned out to be a significant improvement, as did new rotor designs which proved better able to manage heat and therefore resist cracking.

“The early adopters in North America were emergency vehicles for their high-energy stops, and then fuel haulers and hazmat haulers for the additional margin of safety,” said Brian Andrews, engineering manager at Cummins-Meritor. “Over the past five years or so we’ve seen a significant ramp-up in the in the take-rate for air disk brakes in the North American market.”

Andrews showed a chart tracking ADB uptake from the early part of the millennium to the present. Uptake for tractors grew from about 5% to 10% between 2011 and 2014 roughly. Adoption plateaued between 2014 and 2016 before trending steeply upward into 2023. Overall, tractor uptake went from less than 5% in 2011 to about 50% last year.

Some technician training will be needed in fleets new to disc brakes. The tribal knowledge isn’t yet predominant. That will improve with time.

We saw a similar adoption profile for trailers, but at lower rates. Uptake was almost flat at less than 5% between 2011 and 2016, when growth took off.

As of 2023, trailer adoption was a little better than 15% and trending upward.

Among the drivers of ADB adoption were the National Highway Traffic Safety Administration’s revised stopping distance rules. Andrews said OEM met the Phase One requirements easily enough with slightly larger drum brakes, but the Phase Two rules in 2013 that applied to heavier trucks needed ADB on the steer axle at least to maintain the margins on stopping distance.

“There was an increased focus on safety within the industry around that time [2012-2014],” he said. “And designs continued to be optimized while cost and weight were being taken out, and volumes were improving so ADB were becoming more cost effective.”

Packaging and compatibility also improved during those years, with more suspensions becoming ADB-friendly. And standardization improved, including the rotor position, where the OEMs began using the same torque offsets and hub offsets. As well, caliper mounting bolt patterns became standardized across more OEMs.

“Over time, the OEMs started making ADBs an unpublished option in their data books and eventually almost all of them changed over to disc brake as their standard,” said Andrews. “And with everybody adopting at a higher rate, parts availability improved, and the aftermarket started to open up.”

While some believe we’ve reached a tipping point with ADB, Mark Holley, director of marketing and customer solutions, wheel-ends, Bendix Commercial Vehicle Systems, said it’s still worth doing a gut-check, to see where you stand on the issue.

“The drum versus disk discussion is still a healthy one to have,” he said. “Should I just follow the crowd and go with aid disc brakes, or are there other things I should consider?”

The Plus-side of ADB

With multiple advantages over drum brakes, fleets need to consider with of the benefits matter most, if at all, before making the jump.

With air disc brakes, it is more difficult to see the friction material, especially if you’re doing a wheels-on visual inspection. Some fleets are using borescopes with lights to aid in the inspections or turning to pad-wear sensors.

ADB offer quantifiable gains in performance, not necessarily in stopping distance, but stopping distance over multiple hard-braking events. Holley said ADB are virtually resistant to brake fade because rotor expand into the brake pads as they heat up, as opposed to drum brakes which experience lower braking force as the hot drum expands away from the brake linings.

“Over 10 hard stops, the difference in stopping distance between drum and disc can increase from one or two car lengths to up to 75 feet [with drums],” he said.

That can make the difference between a crash and a near miss. If driver and recruiting and retention is a consideration, ADBs almost always win over the hearts of drivers. They like the performance and the safety margin ABDs offer, and they like the passenger-car feel of disc brakes.

And they really don’t mind the fact that air disc brakes are almost a get-out-of-jail-free card at a CVSA Level 1 inspection. Chances of being placed out of service from a drum brake defect are much greater.

In fact, CVSA inspectors usually just move on to the next item on their check lists when they encounter an ADB-equipped truck. ConMet’s director, technical services, Roger Maye relayed a little tale he had heard about how CVSA inspectors approach their jobs. It confirmed the benefits of ADB when it comes to keeping CSA scores in check.

“The highway patrol officers have figured out the path of least resistance to do their jobs,” he told the audience. “There’s a lot less to inspect on an ADB equipped vehicle. ADB fleets have told us they get inspected more frequently, but they’re not getting the citations from those inspection. It’s easier for the inspector to inspect, but they’re finding less, so fleet’s exposure is less for brake inspections.”

Perhaps the most important metric that plays in ADB’s favor, at least as far as maintenance managers are concerned, is total cost of ownership.

Holley acknowledged that upfront cost is higher, but lifecycle cost can be considerably lower, especially with short trade cycles.

“Once you get to the second and third year, you will see most on-highway and over-the-road applications are TCO positive,” he said.

Timing is everything, sometimes. In panic stops, disc brake apply faster and have more stopping force.

There’s no need to grease the ADB during maintenance intervals, lining life is generally better than standard brake linings, but that can be application dependent, and pad changes require a fraction of the time it takes to replace brake linings and drums.

It’s entirely possible a fleet could run a truck for three to four years with no more brake maintenance than a pad change, and some fleets even manage to avoid that if the truck is traded off before a change is necessary.

The Downside of ADBs

That said, ignoring the required maintenance or trying to push pad life too far can easily upend the TCO calculation. What works with CVSA inspectors can work against fleets that are not proactive.

“With air disc brakes, it is more difficult to see the friction material, especially if you’re doing a wheels-on visual inspection,” Holley said. “You have to bend over to really get in there and see the pad thickness. Some fleets are using borescopes with lights to see in there. That saves a ton aggravation — and time. Fleets can also consider pad-wear sensors or continuous wear sensing as an option. That’s gaining some traction.”

The last thing you want to do is replace a rotor damaged by worn pads. That’s an expensive proposition.

Technician training can also be a concern, especially with trailer ADBs. There are too few of those systems in the market for sufficient numbers of technicians to have exposure to them.

Inexperienced techs can lead to incomplete or less than thorough inspections, which can lead to expensive problems.

And there are acknowledged problem with ABS tone-ring corrosion.

With air disc brakes, it is more difficult to see the friction material, especially if you’re doing a wheels-on visual inspection. Some fleets are using borescopes with lights to aid in the inspections or turning to pad-wear sensors.

“Tone-ring corrosion certainly is a major issue, but I know manufacturers are working on new designs, and new ways to attach the tone-rings, as well as experimenting with coatings,” Holley said. “You’ll see more of that to address this issue.”

The final acknowledged downside is abrasive environments. Experience has shown that dirt and debris from certain environments, like construction and off-road applications, can shorten pad and rotor life. But it’s not a universal problem, mind you.

Pad and rotor shields offer a solution in some applications. The operative word here is to consider the application.

“We do know that drum brakes tend to be a little more forgiving in some of the more abrasive environments like construction, heavy vehicle, industrial, especially when you’re getting a lot of dirt and debris into there,” said Cummins-Meritor’s director of engineering, Joe Kay. “We’ve been saying this for a while now: pick the right product for the application.”

The Fleet Point of View

Two fleets participated in the panel discussion. Joliet, Illinois-based GP Transco and Maverick of North Little Rock, Arkansas. Both report positive experiences overall with air disc brakes.

Alex Gorno, maintenance director, at GP Transco said he reaps the benefits of ADB thanks most to short trade cycles. His trucks run 3.5 years or about 370,000 miles. The average age id the fleet today is 19 months for tractors and 36 months for the fleet of dry van trailers.

“We are capturing the benefits of increased performance of ADB, and also because of our shorter life cycle, we have reduced maintenance costs as well.”

Gorno reported repair frequency for the fleet of 600 tractors was 30 instances 2023 where ADB needed servicing on one axle, and just three instances where brakes on two axles needed replacement.

For this 1000-unit trailer fleet, he reported a total of 45 repairs last year. Meanwhile, Maverick’s maintenance director, Brent Hilton, went into a little more detail on the mileage brake pads were changed out on various model year tractors and trailers.

He’s running 1,650 power units and 2,480 trailers — mostly flatbeds. Tractors have been spec’d with air discs since 2019 and trailers since 2008.

Trade cycles on tractors is about 4 years and 400,000 miles. The average age of the fleet is 2.5 years.

The spreadsheet he showed indicated many of his later model tractors were traded without a pad replacement. The VMRS codes for most of the brake repairs in his system were “worn, replaced,” so very little unexpected maintenance was performed.

“We had some supply chain issues a few years back that proved pretty costly, because of parts shortages and related downtime,” he noted. He also cautioned fleets to stay on top pf the PMs and the recommended maintenance intervals. “Some of these failures on the road can get real costly, real quick.”

Are Air Disc Brakes Worth It?

It’s still an appropriate question to ask, even with most of the growing pains behind them. They will continue to improve and suppliers will come up with solutions for the nagging problems, like corroded tone-rings and the pad wear inspection challenges.

There are upsides and downside to spec’ing ADBs on trailers, especially those left out in the wild for extended periods. They don’t require a lot of hands-on maintenance, but missed inspection intervals can lead to costly problems.

Availability of parts and trained service technicians can be problematic in certain lanes. Before going all in, make sure you have a reliable service network.

And don’t overlook the need for technician training on ADBs. They are still relatively new, and familiarity may not be what it is with drum brakes. There will need to be some investment made there.

And finally, try to determine if your new ADBs will live long and prosper in your specific application. With hundreds of millions of miles behind them now, OEMs and suppliers will be able to provide clearer answers to these questions.

Be sure you ask before jumping in.

-

AuthorPosts

- You must be logged in to reply to this topic.