Trucker Access › Forums › Diesel News › ZF’s AxTrax 2 Electric Axle Shows its Stuff – Fuel Smarts

- This topic has 0 replies, 1 voice, and was last updated 8 months, 2 weeks ago by

EazyRiDer66.

EazyRiDer66.

-

AuthorPosts

-

July 16, 2024 at 11:30 am #30023

EazyRiDer66Keymaster

EazyRiDer66Keymaster

ZF’s demonstrator truck for its AxTrax 2 e-powertrain was a stock Kenworth T680, with no alterations other than the installation of the two e-axles.

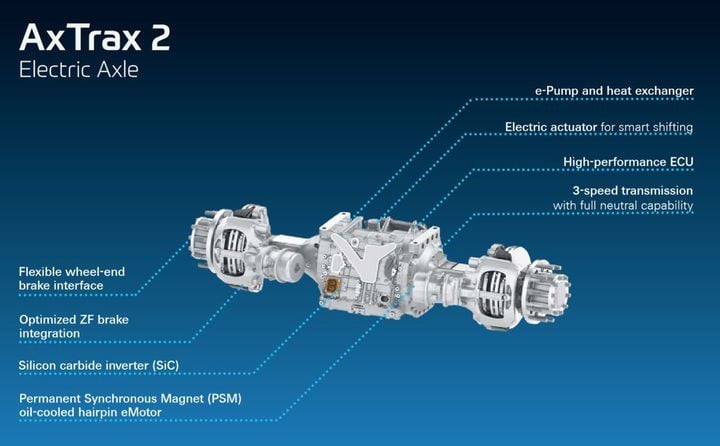

In the battle for efficiency, weight reduction, range and frame space, builders of battery-electric trucks need all the allies they can muster. For ZF, this meant stepping into the battle with AxTrax2, a scalable and modular e-axle fitted with a motor, inverter, ECU, actuator and transmission.

ZF took the wraps off AxTrax 2 last year at ACT Expo. This year, ZF had a truck on the ground fitted with the new e-mobility kit, and they offered demo drives.

A Premium on Chassis Real Estate

AxTrax 2 is a compact, axle-based system designed to help maximize the available space for batteries while opening new chassis design options for OEMs.

According to ZF, AxTrax 2 can be fully synchronized with key vehicle functions, including braking, ADAS and automated driving systems. It also enables advanced digital and telematics systems via CAN bus to communicate and share e-axle system information.

The system is offered in two configurations: AxTrax 2 and AxTrax 2 dual.

The dual version, designed for heavy-duty Class 8 service, has two motors, two inverters, 2 actuators, and a three-speed transmission. It delivers 380 kw continuous power with 40,418 lb-ft of peak output torque.

AxTrax 2 integrates a single motor, inverter, ECU, actuator and a three-speed transmission. It’s designed for a broader range of applications from single-axle to 6×4 (Class 3-8). It delivers 210 kw continuous power and 19,162 lb-ft of peak output torque.

ZF’s AxTrax 2 is offered in two configurations; single motor/inverter for Class 3-8 applications, in 6×2 or 6×4 chassis. The AxTrax 2 dual is for heavier Class 8 applications. It features dual motor/inverter/actuator configuration.

Nominal system voltage is 650V, with an optional 750V system.

Both models replace the traditional powertrain from the engine to the drive axle, opening up frame space for batteries and related components. They fit into the space of the conventional axle(s), while accommodating existing wheel-end and brake components.

Integration Enhances Functionality

ZF says the AxTrax 2 is the only heavy-duty Class 8 axle with a coaxial design. That means the torque is distributed evenly across all four wheel-ends as needed, and it’s all electronically managed. A planetary gear set at each end of the motor takes over the differential function.

It’s lighter and more compact than a traditional differential. The smaller profile eases packaging restrictions and while opening up more suspension spec’ing opportunities.

Drive axles are not very photogenic, but this image shows the rear axle nestled between the shock absorbers.

“The setup is a master and slave arrangement,” said Christian Feldhaus, ZF Group’s vice president of driveline, commercial vehicle solutions. “Because both axles are driven, they need to be balanced.”

When shifting gears, for example, rather than breaking torque during the gear change, the transmissions on the axles shift sequentially so at least one axle is always driving the truck.

The truck launches in 1st gear typically and shifts into 2nd around 20 mph. The shift to 3rd gear takes place between 30 and 40 mph.

There’s also a true neutral in the transmission, which reduces parasitic drag from the non-driving axle while coasting (if regen braking is not desired).

It’s also useful if towing is required. It provides a mechanical disconnect between the wheels and the motor to prevent driveline damage.

“That kind of balanced efficiency is most important here, as we all know how important preserving battery capacity is,” Feldhaus said.

During my brief test drive of the truck, a Kenworth T680 fitted with AxTrax 2, the shifting was utterly seamless, both up and down. Drivers no longer really need to know what gear they are in, and this axle grouping certainly won’t betray any secrets.

ZF made no modifications to the truck from stock except the installation of the AxTrax 2 drive e-axles.

Electronic Brake Control

The axles also help manage the braking task by automatically blending regenerative braking capacity with application of the service brakes — when needed.

When the driver’s foot comes off the accelerator pedal, the electronic braking system will prioritize regen braking, but will also apply the service brakes if necessary.

“The driver won’t even notice it. It won’t feel any different,” said Dirk Wohltmann, director of engineering, commercial vehicle solutions at ZF, who accompanied me on the demo drive.

“The driver just demands a specific brake deceleration and gets it. It doesn’t matter if you’re fully laden or empty, if you’re going uphill or downhill. It’s all managed by a closed-loop deceleration controller.”

This function requires EBS — sometimes called brake-by wire — functionality. It also works with North American standard ABS brake controllers, but you won’t see maximum possible efficiency from that system.

[embed]https://www.youtube.com/watch?v=JyVM5fk_NiI[/embed]

While I have only a few days of experience driving battery-electric trucks, I’ve figured out how to manage speed with just the accelerator pedal — so called one-pedal operation.

The regen braking function is not on/off, based on the pedal position. As you back off the pedal slightly, you can feel the effects of a small degree of regenerative brake. Remove the foot completely and you get the full impact, based too on the regen brake settings.

This system made control of the regen function very precise and importantly, quite comfortable.

Driving Observations

Wohltmann and I got deep into the weeds during the demonstration drive I had at ACT Expo. Far deeper than readers would likely care to follow in a long technical story. What opened my eyes was the level of control engineers have over the basic operation of the truck by means of integration with components designed to function as a single system.

The average truck driver would never appreciate everything that’s going on beneath the floorboards, but he or she would quickly realize the benefits. For all the nay-sayer drivers who insist they’ll never get into an electric truck, all they need to do is try something like this and all that uncertainty would vanish.

It’s remarkable progress from the first electric truck I ever drove back in 2015 (also at ACT Expo, by the way.)

-

AuthorPosts

- You must be logged in to reply to this topic.