Trucker Access › Forums › Diesel News › Electric Trucks a Fit for Innovator Blanchette at QCD – Fleet Management

- This topic has 0 replies, 1 voice, and was last updated 5 months ago by

EazyRiDer66.

EazyRiDer66.

-

AuthorPosts

-

June 22, 2024 at 5:45 am #26746

EazyRiDer66Keymaster

EazyRiDer66Keymaster

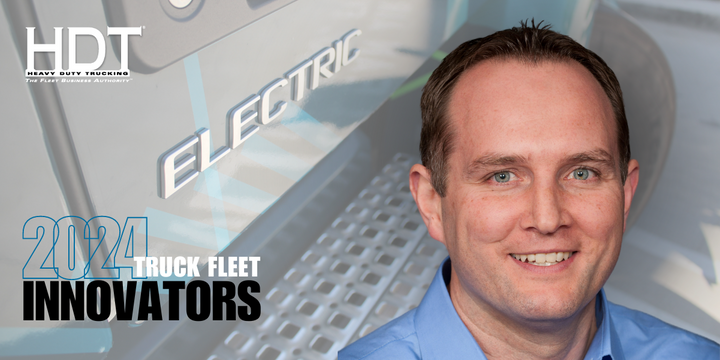

Shane Blanchette us group vice president-operations for QCD, a national food service logistics supplier.

Image: HDT Graphic | QCD photos

When you’re in charge of continuous improvement at a trucking fleet, sustainability is part of that. But at Quality Custom Distribution, Shane Blanchette has been taking it to the next level.

Blanchette, an HDT 2024 Truck Fleet Innovator, is group vice president-operations for QCD, a national food service logistics supplier.

QCD took delivery of its first Volvo VNR Electric truck in 2021 as part of the Volvo LIGHTS electric-truck demonstration program.

That was the first zero-emission, battery-electric truck to be deployed in QCD’s fleet of more than 700 vehicles, but it definitely was not the last.

QCD took delivery of its first Volvo VNR Electric truck in 2021 as part of the Volvo LIGHTS electric-truck demonstration program.

Photo: Quality Custom Distribution

A Golden State Foods company, QCD provides custom distribution services to thousands of restaurants. Each year, QCD makes over 1 million last-mile deliveries from its 26 temperature-controlled distribution centers. Blanchett started working for the company eight years ago and was senior director of continuous improvement before moving into the VP role.

Why is QCD Adopting Battery-Electric Trucks?

While regulations such as California’s Advanced Clean Fleets rule play into the decision to electrify, big customers such as Starbucks are also keenly interested in sustainable transportation solutions.

With QCD’s last-mile delivery routes, Blanchette says, the capabilities of electric trucks are a good fit.

“Our average route is under 100 miles. These trucks, the new generation gets up to 275 miles. It’s been perfect for us because we come back, and they still have anywhere from a 40 to 50% charge remaining on them.”

Drivers love the trucks for their smooth ride and quiet operation.

“We do make sure that they go through a little extra training,” Blanchette says, because their driving techniques can affect the performance.

“When you get into the regen braking and things like that, because we have a goal of 2 kilowatt hours per mile, if you’re depending on driver behavior, that that can fluctuate. So we kind of coach them up in that area.”

QCD drivers love the Volvo VNR Electric trucks for their smooth ride and quiet operation.

Photo: Quality Custom Distribution

Solar Microgrid to Power 30-Truck EV Fleet

QCD has two electric fleet projects in southern California, one in Fontana and one in La Puente.

The Fontana location is replacing 15 diesel trucks with Volvo VNR Electric models, using electric chargers powered by the utility grid.

The La Puente location is in the process of installing a solar-powered microgrid that will support 30 battery-electric tractors.

“We’re not requiring an electric grid upgrade,” he says. “Normally, with a fleet that size, it would essentially double the capacity [needed]. But because we have the solar charging and the battery energy storage, we’re able to manage the system, so we won’t need a utility upgrade from our provider.”

He says the utility did have to review and approve the design, but didn’t have to add electric grid capacity to serve the facility.

That project is scheduled to be complete by the end of the third quarter. Currently it’s using temporary chargers, which gives is the capacity to run 10 of the electric trucks.

Blanchette has been working on this project since 2021.

“They are complicated projects,” he explains. “A lot of it’s a process, you know, so you’ve got to get your partners and the key stakeholders and get the project timing [coordinated.]”

And part of that process is obtaining grant funding, which he says is supporting about 25% of the $20 million project.

[embed]https://www.youtube.com/watch?v=C1hTvtw5vzo[/embed]

Making Life Easier for Quality Custom Distribution’s Delivery Drivers

Even though food distribution doesn’t have the kind of driver turnover long-haul trucking does, driver retention is still a concern.

Blanchette says driver were having to deal with multiple technology systems, from ELDs to customer-specific requirements.

“There were multiple systems for these drivers to have to know and log in and out of, different passwords, all those things.”

So the company worked with Samsara to build connectivity between the Samsara application and all those other applications.

With QCD’s last-mile delivery routes, Blanchette says, the capabilities of electric trucks are a good fit.

Photo: Quality Custom Distribution

“So it feels like a single sign-on experience, and it’s a lot easier. They go into their ELD now, and that automatically can connect them into these different applications that they have to get into.”

As part of that, driver vehicle inspection reports are done via an app, and that information flows directly to QCD’s service provider. Compared to the traditional way of doing DVIRs on paper, he says, “It’s really sped up our operations.” And it’s improved uptime as well.

Making Deliveries Easier for Drivers

QCD also has made changes to its delivery process, with drivers using powered equipment, electric jacks that have become small enough to make it practical — instead of using hand trucks.

“They’re not having to move boxes around in the back of the truck or lift anything,” he says.

“Before, we would have to break it down and do more trips,” because powered equipment at the time was too large to easily navigate through customer stores. “But now the equipment’s allowing us to bring that right in.”

“The driver feedback has been amazing,” Blanchette says. “It’s helping retention, turnover’s down and most importantly, safety’s improved. They’re telling us, ‘At the end of the day, I don’t feel tired, like I used to,’ and that’s just been a been a huge win.”

After a two-year process of looking for a solution, they started testing it last fall. About 25% of its distribution centers are using this new method, and the company has a rollout plan for full deployment.

QCD has two electric fleet projects in southern California, one in Fontana and one in La Puente.

Photo: Quality Custom Distribution

At QCD, Continuous Improvement is Everyone’s Job

While we honor Blanchette as an HDT Truck Fleet Innovator for his leadership in these innovations, he points out that it’s a company-wide effort.

“We talk about a CI mindset, a continuous improvement mindset, and what we talk about is, yes, we actually have a continuous improvement team,” he says.

“But the message is, part of everyone’s department and job is to be thinking about, how do you get better? Where can improvements be made? And be thinking about your processes from end to end and where are the friction points? What are the pain points, what slows us down? And raise your hand.

“If we’ve been doing something the same way forever, don’t be afraid to question it. That’s what we want, we want to improve, we want to get better.”

-

AuthorPosts

- You must be logged in to reply to this topic.