Trucker Access › Forums › Diesel News › Will Future Truck Tires Be Made From Dandelions and Rice Husk Ash? – Fuel Smarts

- This topic has 0 replies, 1 voice, and was last updated 10 months, 3 weeks ago by

EazyRiDer66.

EazyRiDer66.

-

AuthorPosts

-

May 29, 2024 at 4:30 pm #22904

EazyRiDer66Keymaster

EazyRiDer66Keymaster

New oils and even rubber made from dandilions are among some of the innovations Continetal is using in new green tire prototypes.

Part 1 of The Quest for Greener Truck Tires examined why it is so important for tire makers to develop environmentally friendly truck tires. But how, exactly, are they going about doing so?

Optimizing truck tires for fuel economy and retreading are well-established practices in trucking. But designing truck tires with Earth-friendly materials and manufacturing processes requires tire makers to essentially go back to the drawing board.

But it’s a challenge tire manufacturers cannot turn away from.

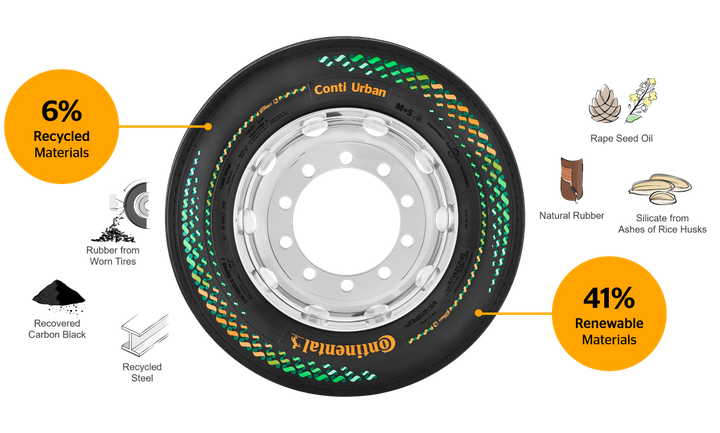

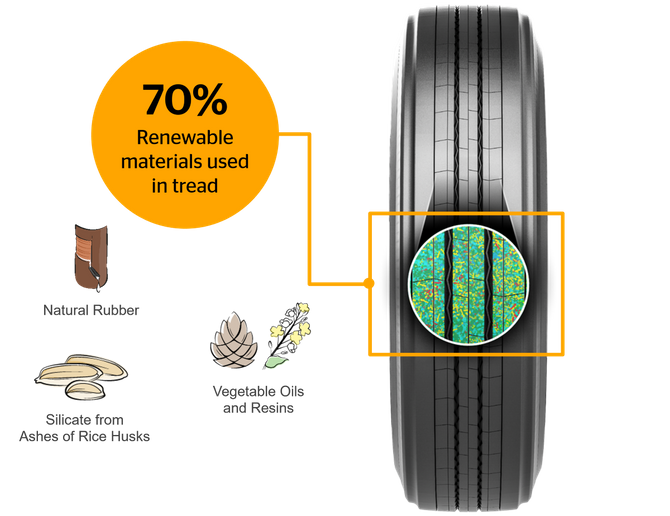

“Step by step, we are already seeing which renewable and recycled alternatives will find their way into tire construction in the future,” says Shaun Uys, head of U.S. market truck tire replacement for Continental Tire.

“These include waste products from agriculture — such as the ash from rice husks — rubber from dandelions, recycled rubber, or recycled polyethylene terephthalate bottles.”

The quest for green truck tires includes expermenting with environmentally friendly substitures for many critical tire-builidng materials.

Recycling tires at the end of their lives for reusable resources is also a priority, Uys adds. In those processes, rubber, steel, and textile cord and other components are separated from one another in a highly sophisticated process. The rubber is then prepared for re-use as part of new rubber compounds.

“Continental’s goal is that by 2050 at the latest, all our tires will be made from sustainable materials,” Uys says. “By 2030 we aim to have over 40% renewable and recycled content in our tires.”

The Search for a Rubber Substitute for Tires

The basic ingredient for any tire is, of course, rubber. Rubber is one of the most unique natural products on the planet. It’s a finicky tree, too, that only grows in specific tropical locations.

And while rubber trees and rubber itself are as green as any other tree, the process of harvesting and transporting rubber to industrialized countries is not. That’s why manufacturers such as Continental and Goodyear are working hard to find green synthetic substitutes for it.

“The specific properties of natural rubber are unique,” Uys notes. “So, a certain amount of natural rubber will very likely always be needed to ensure top safety performance.

“With our dandelion rubber project, we are researching how to industrialize a complementary source of natural rubber. We want to ease the pressure that is being put on traditional growth regions amongst the tropical Internal belt.

“While we are still in the research phase, it remains our aim to one day grow a certain share of the rubber we consume next to our production facilities.”

Goodyear’s Search for Sustainable Rubber

Goodyear is a founding and active member of the Global Platform for Sustainable Natural Rubber (GPSNR). This initiative was launched in 2018 to move the natural rubber industry toward a sustainable natural rubber supply chain.

Goodyear’s concept tire is made with 63% sustainable materials. Here you see samples of 12 of the 15 sustainable materials used.

Goodyear continues to be an active GPSNR member, according to Chris Queen, regional tech director, commercial, Goodyear North America. That includes maintaining a role on the executive committee representing the tire maker category.

In 2022, Goodyear announced a multi-year, multi-million-dollar program supported by the U.S. Department of Defense, the Air Force Research Lab, and BioMADE. The partnership’s goal is to work with Ohio-based Farmed Materials to develop a domestic source of natural rubber from a specific species of dandelion, taraxacum kok-saghyz or TK.

“TK has proven to be a valuable alternative to natural rubber trees,” Queen says. “While rubber trees typically take seven years to produce the latex needed for rubber production, dandelions can be harvested every six months. TK dandelions are also resilient and can grow in more temperate climates, such as Ohio.”

While the rubber produced with TK dandelions is currently planned for use in military aircraft tires, Queen says Goodyear is also looking to accelerate commercialization of TK rubber to be used in other tire applications.

Tire design for electric trucks is critical for optimal range and energy efficency.

Environmentally Friendly Materials

Moving beyond rubber, Queen says the Goodyear team actively seeks sustainable material options that deliver product performance while meeting quality and safety standards. This includes an all-new generation of tires optimized for electric trucks, as well.

“One example of this is our use of soybean oil in select products,” he notes.

“In 2022, we replaced a portion of the petroleum-based oil used in our Metro Miler city transit tires and our Endurance WHA waste haul tires with a bio-based soybean oil compound. The soybean oil in the tire is a bio-based material currently sourced from surplus left over from food applications.”

Queen says Goodyear uses commodity soybean oil in its polymer and tire manufacturing processes in a variety of ways depending on the application.

“Oils in general are used in tire compounds to reduce viscosity and enable the manufacture of rubber compounds that make up the various components of a tire,” he explains.

“They also optimize compound properties like abrasion resistance and tire properties like rolling resistance. Goodyear has a goal of fully replacing petroleum-derived oils in our products by 2040.”

Goodyear also is using a silica product made from residual rice husk ash — a byproduct of rice processing. Queen says rice husk ash (RHA) silica can help deliver performance similar to traditional sand-based silica yet helps reduce waste going to landfill.

“Over the past several years, we have introduced the use of RHA silica in several of our global commercial and consumer tire manufacturing facilities,” he says. “To advance Goodyear’s sustainable material use, our technology teams continually work to investigate new alternative raw materials and incorporate innovative solutions.”

The road to cleaner and greener tires is not an easy one. But companies such as Continental and Goodyear are pushing the boundaries of science to find innovative ways to build tough, reliable, environmentally friendly tires fleets can rely on as the industry moves to more sustainability.

-

AuthorPosts

- You must be logged in to reply to this topic.